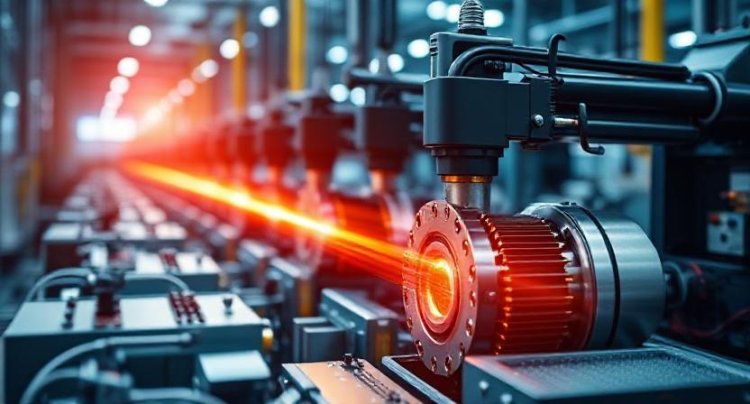

High-Volume Production: Powering the Global Manufacturing Engine

High-volume production is the backbone of modern manufacturing, enabling the mass production of goods to meet the demands of a growing global market. This process involves the large-scale manufacturing of products, often in the thousands or millions, using efficient, automated systems designed to maximize output while minimizing costs. From consumer electronics and automotive components to household goods and medical devices, high-volume production plays a critical role in delivering affordable, high-quality products to consumers worldwide. This article explores the high-volume production process, its applications, benefits, and future trends.

The High-Volume Production Process

High-volume production relies on advanced manufacturing techniques and technologies to achieve efficiency, consistency, and scalability. The process typically involves the following steps:

-

Design and Planning:

The process begins with product design and engineering, where specifications are finalized, and production plans are developed. This stage includes selecting materials, designing tooling, and optimizing workflows. -

Tooling and Setup:

Specialized tooling, such as molds, dies, and fixtures, is created to support mass production. Automated machinery and assembly lines are set up to ensure seamless operations. -

Manufacturing:

Raw materials are processed using techniques like injection molding, stamping, casting, or machining. Automated systems, such as robotics and conveyor belts, streamline the production process. -

Quality Control:

Throughout production, rigorous quality control measures are implemented to ensure that products meet strict standards. This may include inspections, testing, and statistical process control. -

Packaging and Distribution:

Finished products are packaged and prepared for distribution. Efficient logistics systems ensure timely delivery to retailers, distributors, or end consumers.

Applications of High-Volume Production

High-volume production is used across a wide range of industries to meet the demands of mass markets. Some of the most common applications include:

-

Consumer Electronics:

High-volume production is essential for manufacturing smartphones, laptops, tablets, and other electronic devices. The process ensures that these products are produced quickly and cost-effectively to meet global demand. -

Automotive Industry:

The automotive sector relies on high-volume production to manufacture vehicles and components, such as engines, transmissions, and body panels. Automation and precision are critical to maintaining quality and efficiency. -

Medical Devices:

High-volume production is used to produce disposable medical devices, such as syringes, catheters, and diagnostic kits. Consistency and sterility are paramount in this industry. -

Packaging and Consumer Goods:

From food packaging to household products, high-volume production ensures that everyday items are readily available and affordable for consumers. -

Industrial Equipment:

High-volume production is used to manufacture machinery, tools, and equipment for various industries, including construction, agriculture, and manufacturing.

Benefits of High-Volume Production

The adoption of high-volume production offers numerous advantages, making it a cornerstone of modern manufacturing. Key benefits include:

-

Economies of Scale:

High-volume production reduces the cost per unit by spreading fixed costs, such as tooling and setup, across a large number of products. -

Consistency and Quality:

Automated systems and standardized processes ensure that products are manufactured with consistent quality, meeting strict specifications and standards. -

Faster Time-to-Market:

High-volume production enables manufacturers to quickly scale up production and deliver products to market, meeting consumer demand and staying ahead of competitors. -

Resource Efficiency:

Advanced technologies and optimized workflows minimize waste, reduce energy consumption, and improve resource utilization. -

Global Reach:

High-volume production allows manufacturers to produce goods on a global scale, reaching customers in diverse markets and driving economic growth.

Future Trends in High-Volume Production

As technology continues to advance, high-volume production is evolving to meet the demands of a rapidly changing world. Some of the key trends shaping the future of this field include:

-

Smart Manufacturing:

The integration of IoT, AI, and machine learning is transforming high-volume production into smart manufacturing. Real-time data analytics, predictive maintenance, and autonomous systems are improving efficiency and reducing downtime. -

Sustainable Practices:

With growing emphasis on sustainability, manufacturers are adopting eco-friendly materials, renewable energy sources, and circular economy principles to reduce environmental impact. -

Additive Manufacturing:

While traditionally used for prototyping, additive manufacturing (3D printing) is increasingly being integrated into high-volume production for specific applications, such as custom components and lightweight structures. -

Resilient Supply Chains:

The COVID-19 pandemic highlighted the importance of resilient supply chains. Manufacturers are investing in localized production, digital inventory management, and diversified sourcing to mitigate risks.

Conclusion

High-volume production is the driving force behind the global manufacturing industry, enabling the mass production of goods that power our daily lives. From consumer electronics and automotive components to medical devices and industrial equipment, this process ensures that products are produced efficiently, consistently, and affordably. As technology continues to evolve, high-volume production is adapting to meet new challenges and opportunities, paving the way for smarter, more sustainable, and more resilient manufacturing systems

What's Your Reaction?